Kujalan käsittelykeskus

Kiertotalouden asialla – yhteisen ympäristömme parhaaksi

Kujalan käsittelykeskuksen käsittelylaitokset ja toiminnot on esitelty kattavasti ilmakuvan, toimintokohtaisten kuvien, videoiden sekä esittelytekstien avulla. Tervetuloa tutustumaan nykypäivän jätteenkäsittelyyn.

- Offices, emplyee facilities and equipment storage

- ”Jälkimaininki” (the Aftermath) site-specific artwork

- PILLERI waste reception station

- WEIGH STATION, waste reception

- LATE, sorting plant

- MURRE, treatment of energy waste and wood waste

- OILI, processing plant for liquid waste/sludge

- Recyclable waste grounds

- Seepage basins and wastewater pumping station

- Landfill site in use

- Closed landfill

- Biogas pumping facility

- Solar power-plants and the use of renewable energy

- Salpamaa Ltd, Treatment area for concrete, bricks and asphalt

- Salpamaa Ltd, Treatment areas for contaminated soil

- Nevel Ltd, biogas and composting plant

- Gasum Ltd, biogas upgrading facility

- Nevel Oy, soil processing site

- Asfalttikallio Ltd, asphalt station

- Landscape embankment

- Reclaiming of waste at Kujala Waste Centre

- Pests and vermin

- Odour monitoring

- Making landfill gases into energy

- Processing water from Kujala Waste Centre

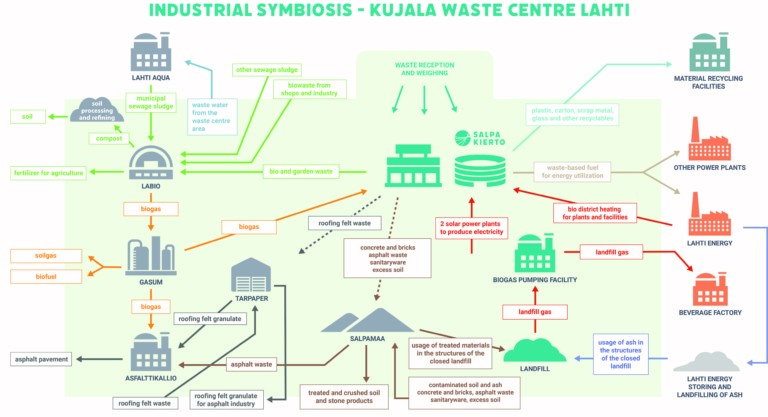

- Kujala Waste Centre Industrial Symbiosis

Offices, emplyee facilities and equipment storage

Building completed in 2001, expanded in 2003 and 2011.

”Jälkimaininki” (the Aftermath) site-specific artwork

The piece of site-specific art, designed by the architecture firm of Tapani Vuorinen, was created from excess soil and recycled glass to add visual interest to the reception area at the waste centre in 2001.

Diamond

The Diamond mural, reproducing the crystal structure of a diamond and glowing with phosphorescent light, gained pride of place on the wall of the Kujala Waste Centre office building in November 2018. The work was created by visual artist Anu Suhonen on commission from Salpakierto Ltd. Diamond was painted on wall panels of the office building in a phosphorescent paint that absorbs light energy during the day and starts glowing when natural light diminishes. The diamond joins in utilising renewable energy – in this case, non-material light energy.

Free as a Bird, Open As the Sky

Sculptor Mika Heinonen’s environmental artwork from 1999–2000, Free As a Bird, Open As the Sky, made of scrap metal, is situated in front of the office building at the waste centre.

PILLERI waste reception station

The services are intended for households and small businesses. It is visited by about 95,000 customers a year. In operation since 2001 PILLERI is one of the six reception stations in the region.

The waste reception stations are located in Asikkala, Heinola, Hollola, Lahti, Orimattila and Padasjoki. Both permanent residents and holiday home owners can use any of the region’s seven waste reception stations, irrespective of municipal borders.

Waste reception stations are intended for household waste other than daily domestic waste. The waste accepted includes building waste, furniture, removal waste, hazardous waste, end-of-life textiles, metal, electrical equipment and garden waste. This waste must not be disposed of in the property´s waste bin.

WEIGH STATION, waste reception

At the Kujala Waste Centre, a weighbridge is used to weigh all skips brought to the centre, loads transported by waste lorries and loads brought in by other heavy vehicles. Waste transported from the centre and all waste transferred internally is also weighed. The loads are inspected, and recorded in statistics. The weighbridge works with an average of 130 vehicle deliveries per day.

LATE, sorting plant

The sorting plant for the Kujala Waste Centre was completed in late 2016, and it entered operation in 2017. The plant processes mixed, construction, and industrial waste and waste for energy production, separating out plastic and metals of various types that can be recycled or processed further from these classes of waste. These materials are delivered to industrial operators for use as raw material. Waste that is unsuitable for recycling will be utilised in energy production. In practice, only stone and other inorganic material goes to landfill for final deposition.

The LATE sorting plant helps to promote circular economy by enabling recyclable raw material to be separated out from waste to be used by the manufacturing industry. The plant complements the sorting of waste at source and aids in work toward the national targets of recycling.

Operating in two-shift rotation, the plant has an annual capacity of 65,000 tonnes. The latest technologies are utilised in the separation, which is based on such factors as the shape, size, and physical and optical properties of the material. The plant’s technical process is perfectly designed for today’s needs.

The receipt terminal, completed in 2009, serves as the sorting plant’s reception hall. In this reception hall, some of the waste is fed to mechanical treatment systems via a demolition-sorting grab, while the remainder is transported directly for use as materials or in energy production.

MURRE, treatment of energy waste and wood waste

The facility transforms wood waste and waste with plastic or fibre content which is unsuitable for recycling into fuel (SRF) for power plants. During the process the waste is crushed, and magnetic and non-magnetic metals are removed. The capacity for treatment is 60,000 tonnes of waste per year. The facility was introduced in 2011.

The MURRE facility has separate treatment lines for waste with plastic or fibre content and wood waste, which enables optimal processing of these categories of material and ensures the best possible heat value from the end product.

Energy waste that is collected separately gets fed into the crusher, and once crushed it is transported to the magnetic system, where both magnetic and non-magnetic metals are separated from the waste. The resulting energy waste is ready for use as recycling fuel.

The MURRE system can handle approximately 60,000 tonnes of waste each year, consisting of:

- 30,000 tonnes of recycled fuel (SRF)

- 20,000 tonnes of recycled hog fuel

- 10,000 tonnes of twigs and logging waste

The MURRE facility also receives energy and wood waste to be crushed on behalf of the customer. In addition, it can be used to destroy products that, for whatever reason, must not reach the market.

Fuel made of energy waste is delivered to Lahti Energia’s Kymijärvi II power plant, where it is used to produce electricity and district heating. The fuel is fumigated at high temperature. Pure eco-gas is burned in a natural gas burner that produces 50 MW of electricity and up to 90 MW of heat.

Take a look at the journey of energy waste: From home to home – from waste to energy and light.

OILI, processing plant for liquid waste/sludge

The facility uses the Geotube process, which mechanically handles liquid waste. This process is suitable for sludge from rainwater tanks and oil and grease traps as well as sewage sludge and industrial sludge. The facility can handle approximately 10,000 tonnes of liquid waste each year. The facility was taken in use in 2007.

The sludge is pumped into a geotextile sack which allows liquid to pass through it while retaining solids inside. Water is then directed into a drain and solid materials are sent to an appropriate processing plant, depending on the waste type.

After the liquid has been removed, only approximately 10–20% of the original quantity of waste remains as solids.

Grease is being fermented, oil and industrial solids are being treated as hazardous waste. Rainwater and sand separation channel sands are either stabilised or placed in the landfill.

Water filtered out through the Geotube process is pumped into the sewerage system, from which it runs to the wastewater treatment plant for purification. Samples are taken and tested regularly to ensure that the water is safe to enter the sewer system.

The geotube process is not suitable for liquid waste containing harmful substances in soluble form. It is not highly suited to treating industrial paint sludges either.

The geotube process is not suitable for liquid waste containing harmful substances in soluble form. It is not highly suited to treating industrial paint sludges either.

Water filtered out through the Geotube process is pumped into the sewerage system, from which it runs to the wastewater treatment plant for purification. Samples are taken and tested regularly to ensure that the water is safe to enter the sewer system.

Geotube represents the best available technology (BAT). The waste is treated in safe and appropriate facilities using appropriate methods.

Recyclable waste grounds

Tarmacked recyclable waste grounds serve as interim storage and processing areas for twigs and brushwood, tree stumps, metal, gypsum, roofing felt and window glazing. Recyclable waste is transported to facilities that process it into new raw materials. Approximately 5.3 hectares is used for the reception and storage of recyclable waste.

- Tree stumps are crushed and used as a bulking agent for composting plant.

- Twigs are crushed and the chips are used for energy generation.

- Garden waste is transferred to a composting plant to be used as mixing and support material. Some garden waste, such as apples, is suitable for biogas generation.

- Metals are used as raw material by the steel and foundry industry.

- Glass waste goes to the production of foam glass, glass wool and float glass.

- Bitumen roofing material is suitable for the manufacture of asphalt.

- Gypsum is recycled as raw material for new gypsum sheets.

- Items of furniture are crushed, and recyclable materials, such as metals, are recovered. The remaining waste is used for energy generation.

Seepage basins and wastewater pumping station

At the Kujala Waste Centre, seepage from outdoor landfill areas and waste water generated by the processing plants and composting areas are directed to the detention basin for concentrated wastewater and from there to Lahti Aqua Ltd’s wastewater treatment facility in Ali- Juhakkala. Mildly contaminated water from the grounds for treating contaminated soil and similar outdoor areas is collected in a separate detention basin and channelled into the ground after sand filtration.

Landfill site in use

The total area of the landfill site in use is 5.4 hectares. Its foundations comply with the latest regulations. Today, only waste from construction and industrial operations that cannot be recycled or reused, such as asbestos and tiles, are disposed of in the landfill (3,000 tonnes per year). Organic waste may not be taken to the landfill.

Closed landfill

The closed landfill was decommissioned in 2007. The site’s area is 24 hectares. When waste decomposes in oxygen-free conditions, it generates biogas, which consists mainly of methane and carbon dioxide with small amounts of sulphur compounds.

Landfill gas has been collected at Kujala since 2002. Collecting landfill gas cuts down on odours in the local environment and reduces the amount of greenhouse gases released into

the atmosphere. The landfill is equipped with gas collection wells and channels, and drainpipes for transferring wastewater for treatment.

The decommissioned landfill will continue to be maintained and monitored for at least 30 years. The construction of a reactive barrier in the eastern area of the closed site began in summer 2020. This work will take 10–15 years. Clean excavation soil, mildly contaminated soil, stabilised contaminated soil and lime and ash generated by waste incineration are used for covering the landfill site.

Biogas pumping facility

The gas collected from the closed landfill is transferred from the collection wells to a biogas pumping facility. The gas is directed to the nearby Hartwall beverage plant, where it is used to generate process steam and heat for the plant’s processes.

Solar power-plants and the use of renewable energy

The company’s offices obtain their energy entirely from renewable sources. By using renewable energy, the company wants to promote positive climate impacts and reduce its carbon footprint, but it also strives to support the development of renewable energy technologies. It aims to increase self-sufficiency in energy production. Two solar power plants were built at the Kujala Waste Centre in autumn 2017, which produce approximately 80 MWh of solar power per year. In addition, the centre enhanced its energy efficiency by replacing its old lighting solution with LED luminaires in 2018.

Salpamaa Ltd, Treatment area for concrete, bricks and asphalt

Tarmacked recyclable waste area is used for interim storage and the processing of concrete, bricks, asphalt and sanitaryware.

- Concrete and bricks are crushed and utilised in landscaping

- Sanitaryware is crushed and used in fireplace production.

- Asphalt can be used as raw material for new asphalt

Salpamaa Ltd, Treatment areas for contaminated soil

Salpamaa Ltd receives and treats contaminated soil. Contaminated soil and soil containing waste are first screened. Then the soil is stabilised and compacted into a non-toxic form. Pursuant to centre´s environmental permit, the treated soil is utilised in the structures built to cover the closed landfill. The area of the grounds for contaminated soil is 3.4 hectares.

According to the Environmental Protection Act, soil is contaminated if it contains waste or materials that create a hazard or risk to health and the environment or that reduce comfort. Soil purification is always subject to a decision by environmental authorities. The decision may include provisions addressing the organisation and control of the purification measures.

Soil that is severely contaminated or that contains waste is taken to the CSSA site at the Kujala Waste Centre for preliminary treatment by sifting. The pre-treated severely contaminated soil is processed into non-toxic form. The main treatment method is stabilisation and compacting, after which the soil is deposited in the embankment surrounding the waste centre.

Soil that is only slightly contaminated is used directly or after sifting at the Kujala Waste Centre for restructuring decommissioned landfills or as preliminary cover, or it is used in daily maintenance of the landfill for non-hazardous waste.

The treatment methods represent BAT in accordance with the environmental permit procedure, such that the treatment does not cause any other environmental pollution.

Nevel Ltd, biogas and composting plant

The biogas plant produces raw biogas from the biowaste and garden waste collected separately and wastewater sludge via a dry fermentation process. The remaining material is transferred to the composting plant for composting. The composting products are used in agriculture and the manufacture of growing media.

The plant can handle approximately 82,000 tonnes each year. This is recycled into 50 GWh of biogas and 22 000 tonnes of compost. Recycling rate is 98 %. The amount of biogas produced is equivalent to the annual fuel consumption of 4,500 cars. The plant covers approximately 5 hectares. The composting plant was taken in use in 2005 and the biogas plant in 2014.

The Gasum biogas upgrading facility in Kujala area upgrades the raw biogas generated by LABIO Ltd’s biogas plant, producing biogas that is similar to natural gas in composition. The biogas, which is suitable for use as transport fuel, is then fed to Gasum’s natural gas network.

Gasum Ltd, biogas upgrading facility

The facility upgrades the raw biogas generated by LABIO Ltd’s biogas plant, producing biogas that is similar to natural gas in composition. The biogas, which is suitable for use as transport fuel, is then fed to Gasum’s natural gas network.

Nevel Oy, soil processing site

The site is used to produce soil from compost product from the composting plant. Compost mass is matured in outdoor piles for 4-12 months.

Asfalttikallio Ltd, asphalt station

The company manufactures asphalt in its facility at Kujala Waste Centre. Crushed bitumen produced from roofing felt can be used as raw material in asphalt production.

Landscape embankment

Pursuant to the centre’s environmental permit, a landscape embankment has been built along the eastern and southern sides of the waste centre. Soil from earthworks and contaminated soil stabilised at the centre are used in the structures of the embankment.

Reclaiming of waste at Kujala Waste Centre

The role of waste management services in the circular economy is to promote recycling by recovering all materials from waste treatment processes that can be reused as raw materials in order to preserve natural resources. The goal is to reduce the quantity of waste used for energy production and minimise the amount of waste disposed of in landfill.

Thanks to new energy recovery solutions, only about 0,5-1 % of incoming waste in the operation region now ends up in landfill. In a year approximately 53-55% of all materials, with consideration to the municipal waste flows from the various parties active in the region, end up as input to recycling. Waste that is unsuitable for use as raw material will be directed to energy generation. The company’s core strategic objective is to reduce the percentage of waste used for energy generation and increase the share that enters recycling.

The company’s annual reports and environmental reviews (in Finnish) offer more information about the waste utilisation rates in each respective year.

These three good practices of Circular Economy are presented in the database of Interreg Europe from Päijät-Häme region:

- Good practice: Effective municipal waste source separation and recovery – Päijät-Häme region

- Good practice: Smart solutions for waste separation

- Good practice: Utilisation of biowaste streams – bio-based industrial symbiosis

Pests and vermin

Waste treatment also attracts nuisance animals that come to the area in search of food. The number of these animals, which include seagulls, crows and rats, is reduced by receiving all waste that will undergo processing on indoor premises.

A bird inspector monitors the number of birds in the area weekly. The number of rodents in the area is reduced via the use of poison and by maintaining the area’s infrastructure.

Seagull counts have been performed regularly, following the same method since 1997 until 2024. The number of seagulls in Kujala is directly proportional to the amount of food available. Transfer of mixed waste for energy use via the LATE sorting terminal began in 2009. This considerably reduced the numbers of seagulls (herring gulls, lesser black-backed gulls, and black-headed gulls) feeding both in Kujala and at other counting locations.

Birds belonging to the crow family have been counted at the Kujala Waste Centre since 2010–2011. The jackdaw is the most common of these birds at the centre.

We monitor, in addition to seagulls, the presence of other animals in the area. Rats, which are in search of readily available food just as seagulls are, constitute a particular focus of monitoring. In addition, deer, foxes, and European badgers have been seen at the landfill or nearby.

The environmental indicator figures in the company’s annual reports and environmental reviews provide more information about the presence of pests in the area (in Finnish).

Odour monitoring

9 to 12 residents who live within 3.5 km of the waste centre participates in the odour board in daily basis. The participants are trained to identify odours originating from the waste centre: from the landfill site, from the processing and bio-waste and from Gasum’s gas purification facility.

Enwin TOM odour modelling system

Models the spreading of odours to the surroundings in real time. The system depicts on a map how widely and in which direction odours travel from the waste centre. Performed on the basis of the times of the odour observations with a clear cause and wind directions at the time.

The program is used for the processing of feedback on odours and the creation of statistics.

With the odour information, odours generated by the waste centre can be identified, enabling the targeting of preventive measures.

Feedback on odours can be provided on company’s website.

Collecting landfill gas cuts down on odours in the local environment and reduces the amount of greenhouse gases released into the atmosphere from the landfill.

The environmental indicator figures in the company’s annual reports and environmental reviews provide more information about the odour occurence in the area (in Finnish).

Making landfill gases into energy

As waste decomposes in oxygen-free conditions in a landfill, landfill gas is generated. This biogas consists mainly of methane and carbon dioxide with small amounts of odourous sulphur compounds.

Landfill gas has been collected at Kujala since 2002. The gas collected is piped to Hartwall´s heating station, where it is used to generate process steam for the soft drinks plant. Collecting landfill gas cuts down on odours in the local environment and reduces the amount of greenhouse gases released into the atmosphere.

Gas production in the closed landfill has been found to be on the decline in recent years; this has also reduced the amount of gas recovered.

The company’s annual and environmental reviews provide more information about the production of landfill gases too (in Finnish).

Processing water from Kujala Waste Centre

Filtration water from the landfills and other dirty water from waste management processes and facilities are treated at Lahti Aqua Ltd´s Ali-Juhakkala wastewater treatment facility.

Studies indicate that the levels of hazardous substances contained in the wastewater released into the drainage system from the Waste Centre are low. However, the quantity of nitrogen in the wastewater directed from Kujala to the wastewater treatment facility annually corresponds to the amount of nitrogen contained in the domestic wastewater generated by several thousands of people.

Rainwater from the area where contaminated soil is treated and similar outdoor areas is channelled into the ground after sedimentation and sand filtration. Regular rainwater from roads, fields and yards is channelled into the ground as is.

The volume of wastewater pumped into the sewage system and rainwater pre-treated in the area are monitored in real time. The pumping facilities are connected to an automatic alarm system in case of malfunctions. The quality of the wastewater and rainwater, as well as the surface and ground water in the area, are monitored in accordance with the requirements of the environmental permit. Water samples are taken at approximately 30 locations at Kujala two to four times a year.

- Offices, emplyee facilities and equipment storage

- ”Jälkimaininki” (the Aftermath) site-specific artwork

- PILLERI waste reception station

- WEIGH STATION, waste reception

- LATE, sorting plant

- MURRE, treatment of energy waste and wood waste

- OILI, processing plant for liquid waste/sludge

- Recyclable waste grounds

- Seepage basins and wastewater pumping station

- Landfill site in use

- Closed landfill

- Biogas pumping facility

- Solar power-plants and the use of renewable energy

- Salpamaa Ltd, Treatment area for concrete, bricks and asphalt

- Salpamaa Ltd, Treatment areas for contaminated soil

- Nevel Ltd, biogas and composting plant

- Gasum Ltd, biogas upgrading facility

- Nevel Oy, soil processing site

- Asfalttikallio Ltd, asphalt station

- Landscape embankment

- Reclaiming of waste at Kujala Waste Centre

- Pests and vermin

- Odour monitoring

- Making landfill gases into energy

- Processing water from Kujala Waste Centre

- Kujala Waste Centre Industrial Symbiosis

”Jälkimaininki” (the Aftermath) site-specific artwork

The piece of site-specific art, designed by the architecture firm of Tapani Vuorinen, was created from excess soil and recycled glass to add visual interest to the reception area at the waste centre in 2001.

Diamond

The Diamond mural, reproducing the crystal structure of a diamond and glowing with phosphorescent light, gained pride of place on the wall of the Kujala Waste Centre office building in November 2018. The work was created by visual artist Anu Suhonen on commission from Salpakierto Ltd. Diamond was painted on wall panels of the office building in a phosphorescent paint that absorbs light energy during the day and starts glowing when natural light diminishes. The diamond joins in utilising renewable energy – in this case, non-material light energy.

Free as a Bird, Open As the Sky

Sculptor Mika Heinonen’s environmental artwork from 1999–2000, Free As a Bird, Open As the Sky, made of scrap metal, is situated in front of the office building at the waste centre.

PILLERI waste reception station

The services are intended for households and small businesses. It is visited by about 95,000 customers a year. In operation since 2001 PILLERI is one of the six reception stations in the region.

The waste reception stations are located in Asikkala, Heinola, Hollola, Lahti, Orimattila and Padasjoki. Both permanent residents and holiday home owners can use any of the region’s seven waste reception stations, irrespective of municipal borders.

Waste reception stations are intended for household waste other than daily domestic waste. The waste accepted includes building waste, furniture, removal waste, hazardous waste, end-of-life textiles, metal, electrical equipment and garden waste. This waste must not be disposed of in the property´s waste bin.

WEIGH STATION, waste reception

At the Kujala Waste Centre, a weighbridge is used to weigh all skips brought to the centre, loads transported by waste lorries and loads brought in by other heavy vehicles. Waste transported from the centre and all waste transferred internally is also weighed. The loads are inspected, and recorded in statistics. The weighbridge works with an average of 130 vehicle deliveries per day.

LATE, sorting plant

The sorting plant for the Kujala Waste Centre was completed in late 2016, and it entered operation in 2017. The plant processes mixed, construction, and industrial waste and waste for energy production, separating out plastic and metals of various types that can be recycled or processed further from these classes of waste. These materials are delivered to industrial operators for use as raw material. Waste that is unsuitable for recycling will be utilised in energy production. In practice, only stone and other inorganic material goes to landfill for final deposition.

The LATE sorting plant helps to promote circular economy by enabling recyclable raw material to be separated out from waste to be used by the manufacturing industry. The plant complements the sorting of waste at source and aids in work toward the national targets of recycling.

Operating in two-shift rotation, the plant has an annual capacity of 65,000 tonnes. The latest technologies are utilised in the separation, which is based on such factors as the shape, size, and physical and optical properties of the material. The plant’s technical process is perfectly designed for today’s needs.

The receipt terminal, completed in 2009, serves as the sorting plant’s reception hall. In this reception hall, some of the waste is fed to mechanical treatment systems via a demolition-sorting grab, while the remainder is transported directly for use as materials or in energy production.

MURRE, treatment of energy waste and wood waste

The facility transforms wood waste and waste with plastic or fibre content which is unsuitable for recycling into fuel (SRF) for power plants. During the process the waste is crushed, and magnetic and non-magnetic metals are removed. The capacity for treatment is 60,000 tonnes of waste per year. The facility was introduced in 2011.

The MURRE facility has separate treatment lines for waste with plastic or fibre content and wood waste, which enables optimal processing of these categories of material and ensures the best possible heat value from the end product.

Energy waste that is collected separately gets fed into the crusher, and once crushed it is transported to the magnetic system, where both magnetic and non-magnetic metals are separated from the waste. The resulting energy waste is ready for use as recycling fuel.

The MURRE system can handle approximately 60,000 tonnes of waste each year, consisting of:

- 30,000 tonnes of recycled fuel (SRF)

- 20,000 tonnes of recycled hog fuel

- 10,000 tonnes of twigs and logging waste

The MURRE facility also receives energy and wood waste to be crushed on behalf of the customer. In addition, it can be used to destroy products that, for whatever reason, must not reach the market.

Fuel made of energy waste is delivered to Lahti Energia’s Kymijärvi II power plant, where it is used to produce electricity and district heating. The fuel is fumigated at high temperature. Pure eco-gas is burned in a natural gas burner that produces 50 MW of electricity and up to 90 MW of heat.

Take a look at the journey of energy waste: From home to home – from waste to energy and light.

OILI, processing plant for liquid waste/sludge

The facility uses the Geotube process, which mechanically handles liquid waste. This process is suitable for sludge from rainwater tanks and oil and grease traps as well as sewage sludge and industrial sludge. The facility can handle approximately 10,000 tonnes of liquid waste each year. The facility was taken in use in 2007.

The sludge is pumped into a geotextile sack which allows liquid to pass through it while retaining solids inside. Water is then directed into a drain and solid materials are sent to an appropriate processing plant, depending on the waste type.

After the liquid has been removed, only approximately 10–20% of the original quantity of waste remains as solids.

Grease is being fermented, oil and industrial solids are being treated as hazardous waste. Rainwater and sand separation channel sands are either stabilised or placed in the landfill.

Water filtered out through the Geotube process is pumped into the sewerage system, from which it runs to the wastewater treatment plant for purification. Samples are taken and tested regularly to ensure that the water is safe to enter the sewer system.

The geotube process is not suitable for liquid waste containing harmful substances in soluble form. It is not highly suited to treating industrial paint sludges either.

The geotube process is not suitable for liquid waste containing harmful substances in soluble form. It is not highly suited to treating industrial paint sludges either.

Water filtered out through the Geotube process is pumped into the sewerage system, from which it runs to the wastewater treatment plant for purification. Samples are taken and tested regularly to ensure that the water is safe to enter the sewer system.

Geotube represents the best available technology (BAT). The waste is treated in safe and appropriate facilities using appropriate methods.

Salpamaa Ltd, Treatment areas for contaminated soil

Salpamaa Ltd receives and treats contaminated soil. Contaminated soil and soil containing waste are first screened. Then the soil is stabilised and compacted into a non-toxic form. Pursuant to centre´s environmental permit, the treated soil is utilised in the structures built to cover the closed landfill. The area of the grounds for contaminated soil is 3.4 hectares.

According to the Environmental Protection Act, soil is contaminated if it contains waste or materials that create a hazard or risk to health and the environment or that reduce comfort. Soil purification is always subject to a decision by environmental authorities. The decision may include provisions addressing the organisation and control of the purification measures.

Soil that is severely contaminated or that contains waste is taken to the CSSA site at the Kujala Waste Centre for preliminary treatment by sifting. The pre-treated severely contaminated soil is processed into non-toxic form. The main treatment method is stabilisation and compacting, after which the soil is deposited in the embankment surrounding the waste centre.

Soil that is only slightly contaminated is used directly or after sifting at the Kujala Waste Centre for restructuring decommissioned landfills or as preliminary cover, or it is used in daily maintenance of the landfill for non-hazardous waste.

The treatment methods represent BAT in accordance with the environmental permit procedure, such that the treatment does not cause any other environmental pollution.

Closed landfill

The closed landfill was decommissioned in 2007. The site’s area is 24 hectares. When waste decomposes in oxygen-free conditions, it generates biogas, which consists mainly of methane and carbon dioxide with small amounts of sulphur compounds.

Landfill gas has been collected at Kujala since 2002. Collecting landfill gas cuts down on odours in the local environment and reduces the amount of greenhouse gases released into

the atmosphere. The landfill is equipped with gas collection wells and channels, and drainpipes for transferring wastewater for treatment.

The decommissioned landfill will continue to be maintained and monitored for at least 30 years. The construction of a reactive barrier in the eastern area of the closed site began in summer 2020. This work will take 10–15 years. Clean excavation soil, mildly contaminated soil, stabilised contaminated soil and lime and ash generated by waste incineration are used for covering the landfill site.

Landfill site in use

The total area of the landfill site in use is 5.4 hectares. Its foundations comply with the latest regulations. Today, only waste from construction and industrial operations that cannot be recycled or reused, such as asbestos and tiles, are disposed of in the landfill (3,000 tonnes per year). Organic waste may not be taken to the landfill.

Recyclable waste grounds

Tarmacked recyclable waste grounds serve as interim storage and processing areas for twigs and brushwood, tree stumps, metal, gypsum, roofing felt and window glazing. Recyclable waste is transported to facilities that process it into new raw materials. Approximately 5.3 hectares is used for the reception and storage of recyclable waste.

- Tree stumps are crushed and used as a bulking agent for composting plant.

- Twigs are crushed and the chips are used for energy generation.

- Garden waste is transferred to a composting plant to be used as mixing and support material. Some garden waste, such as apples, is suitable for biogas generation.

- Metals are used as raw material by the steel and foundry industry.

- Glass waste goes to the production of foam glass, glass wool and float glass.

- Bitumen roofing material is suitable for the manufacture of asphalt.

- Gypsum is recycled as raw material for new gypsum sheets.

- Items of furniture are crushed, and recyclable materials, such as metals, are recovered. The remaining waste is used for energy generation.

Seepage basins and wastewater pumping station

At the Kujala Waste Centre, seepage from outdoor landfill areas and waste water generated by the processing plants and composting areas are directed to the detention basin for concentrated wastewater and from there to Lahti Aqua Ltd’s wastewater treatment facility in Ali- Juhakkala. Mildly contaminated water from the grounds for treating contaminated soil and similar outdoor areas is collected in a separate detention basin and channelled into the ground after sand filtration.

Solar power-plants and the use of renewable energy

The company’s offices obtain their energy entirely from renewable sources. By using renewable energy, the company wants to promote positive climate impacts and reduce its carbon footprint, but it also strives to support the development of renewable energy technologies. It aims to increase self-sufficiency in energy production. Two solar power plants were built at the Kujala Waste Centre in autumn 2017, which produce approximately 80 MWh of solar power per year. In addition, the centre enhanced its energy efficiency by replacing its old lighting solution with LED luminaires in 2018.

Nevel Ltd, biogas and composting plant

The biogas plant produces raw biogas from the biowaste and garden waste collected separately and wastewater sludge via a dry fermentation process. The remaining material is transferred to the composting plant for composting. The composting products are used in agriculture and the manufacture of growing media.

The plant can handle approximately 82,000 tonnes each year. This is recycled into 50 GWh of biogas and 22 000 tonnes of compost. Recycling rate is 98 %. The amount of biogas produced is equivalent to the annual fuel consumption of 4,500 cars. The plant covers approximately 5 hectares. The composting plant was taken in use in 2005 and the biogas plant in 2014.

The Gasum biogas upgrading facility in Kujala area upgrades the raw biogas generated by LABIO Ltd’s biogas plant, producing biogas that is similar to natural gas in composition. The biogas, which is suitable for use as transport fuel, is then fed to Gasum’s natural gas network.

Salpamaa Ltd, Treatment area for concrete, bricks and asphalt

Tarmacked recyclable waste area is used for interim storage and the processing of concrete, bricks, asphalt and sanitaryware.

- Concrete and bricks are crushed and utilised in landscaping

- Sanitaryware is crushed and used in fireplace production.

- Asphalt can be used as raw material for new asphalt

Reclaiming of waste at Kujala Waste Centre

The role of waste management services in the circular economy is to promote recycling by recovering all materials from waste treatment processes that can be reused as raw materials in order to preserve natural resources. The goal is to reduce the quantity of waste used for energy production and minimise the amount of waste disposed of in landfill.

Thanks to new energy recovery solutions, only about 0,5-1 % of incoming waste in the operation region now ends up in landfill. In a year approximately 53-55% of all materials, with consideration to the municipal waste flows from the various parties active in the region, end up as input to recycling. Waste that is unsuitable for use as raw material will be directed to energy generation. The company’s core strategic objective is to reduce the percentage of waste used for energy generation and increase the share that enters recycling.

The company’s annual reports and environmental reviews (in Finnish) offer more information about the waste utilisation rates in each respective year.

These three good practices of Circular Economy are presented in the database of Interreg Europe from Päijät-Häme region:

- Good practice: Effective municipal waste source separation and recovery – Päijät-Häme region

- Good practice: Smart solutions for waste separation

- Good practice: Utilisation of biowaste streams – bio-based industrial symbiosis

Pests and vermin

Waste treatment also attracts nuisance animals that come to the area in search of food. The number of these animals, which include seagulls, crows and rats, is reduced by receiving all waste that will undergo processing on indoor premises.

A bird inspector monitors the number of birds in the area weekly. The number of rodents in the area is reduced via the use of poison and by maintaining the area’s infrastructure.

Seagull counts have been performed regularly, following the same method since 1997 until 2024. The number of seagulls in Kujala is directly proportional to the amount of food available. Transfer of mixed waste for energy use via the LATE sorting terminal began in 2009. This considerably reduced the numbers of seagulls (herring gulls, lesser black-backed gulls, and black-headed gulls) feeding both in Kujala and at other counting locations.

Birds belonging to the crow family have been counted at the Kujala Waste Centre since 2010–2011. The jackdaw is the most common of these birds at the centre.

We monitor, in addition to seagulls, the presence of other animals in the area. Rats, which are in search of readily available food just as seagulls are, constitute a particular focus of monitoring. In addition, deer, foxes, and European badgers have been seen at the landfill or nearby.

The environmental indicator figures in the company’s annual reports and environmental reviews provide more information about the presence of pests in the area (in Finnish).

Odour monitoring

9 to 12 residents who live within 3.5 km of the waste centre participates in the odour board in daily basis. The participants are trained to identify odours originating from the waste centre: from the landfill site, from the processing and bio-waste and from Gasum’s gas purification facility.

Enwin TOM odour modelling system

Models the spreading of odours to the surroundings in real time. The system depicts on a map how widely and in which direction odours travel from the waste centre. Performed on the basis of the times of the odour observations with a clear cause and wind directions at the time.

The program is used for the processing of feedback on odours and the creation of statistics.

With the odour information, odours generated by the waste centre can be identified, enabling the targeting of preventive measures.

Feedback on odours can be provided on company’s website.

Collecting landfill gas cuts down on odours in the local environment and reduces the amount of greenhouse gases released into the atmosphere from the landfill.

The environmental indicator figures in the company’s annual reports and environmental reviews provide more information about the odour occurence in the area (in Finnish).

Making landfill gases into energy

As waste decomposes in oxygen-free conditions in a landfill, landfill gas is generated. This biogas consists mainly of methane and carbon dioxide with small amounts of odourous sulphur compounds.

Landfill gas has been collected at Kujala since 2002. The gas collected is piped to Hartwall´s heating station, where it is used to generate process steam for the soft drinks plant. Collecting landfill gas cuts down on odours in the local environment and reduces the amount of greenhouse gases released into the atmosphere.

Gas production in the closed landfill has been found to be on the decline in recent years; this has also reduced the amount of gas recovered.

The company’s annual and environmental reviews provide more information about the production of landfill gases too (in Finnish).

Processing water from Kujala Waste Centre

Filtration water from the landfills and other dirty water from waste management processes and facilities are treated at Lahti Aqua Ltd´s Ali-Juhakkala wastewater treatment facility.

Studies indicate that the levels of hazardous substances contained in the wastewater released into the drainage system from the Waste Centre are low. However, the quantity of nitrogen in the wastewater directed from Kujala to the wastewater treatment facility annually corresponds to the amount of nitrogen contained in the domestic wastewater generated by several thousands of people.

Rainwater from the area where contaminated soil is treated and similar outdoor areas is channelled into the ground after sedimentation and sand filtration. Regular rainwater from roads, fields and yards is channelled into the ground as is.

The volume of wastewater pumped into the sewage system and rainwater pre-treated in the area are monitored in real time. The pumping facilities are connected to an automatic alarm system in case of malfunctions. The quality of the wastewater and rainwater, as well as the surface and ground water in the area, are monitored in accordance with the requirements of the environmental permit. Water samples are taken at approximately 30 locations at Kujala two to four times a year.

Kujalan käsittelykeskuksessa Lahdessa vastaanotetaan, välivarastoidaan, käsitellään, hyödynnetään, siirtokuormataan ja loppusijoitetaan yhdyskuntien ja tuotantotoiminnan jätteitä. Kujalan käsittelykeskus on Salpakierto Oy:n päätoimipaikka ja ainoa jätteenkäsittelypaikka. Toiminta on ympäristöluvan alaista.

Vuonna 2001 valmistuneen Kujalan käsittelykeskuksen alueen laajuus on kaikkiaan 70 ha, josta 5,4 ha on käytössä olevaa loppusijoitusaluetta ja 24 ha käytöstä poistettua ns. vanhaa loppusijoitusaluetta. Hyötyjätteiden vastaanotto- ja varastointialueita on noin 5,3 ha. Pilaantuneiden maiden käsittelykentän laajuus on 3,4 ha ja biokaasu- ja kompostointilaitos toimii noin 5 ha:n alueella.

Salpakierto vastaanottaa Kujalan käsittelykeskukseen vuosittain noin 85 tonnia jätettä. Yhdyskuntajätteen osuus on vuosittain noin 60 000 tonnia. Vastaanotetuista jätteistä hyödynnetään lähes 100 % ja kierrätetään reilut 50 %.

Käsittelykeskuksen alueella toimii myös muita jätteen käsittelyyn tai hyödyntämiseen erikoistuneita yrityksiä:

- Salpakierto Oy:n tytäryhtiö Salpamaa Oy vastaa erilaisten maa- ja kiviaineisten vastaanotosta ja käsittelystä

- Nevel Oy (ennen LABIO Oy) vastaanottaa ja käsittelee biojätettä, haravointijätettä ja jätevesilietettä

- Lisäksi alueelta löytyy mm. biokaasun jalostusasema ja asfalttiasema

Oletko kiinnostunut tulemaan ryhmäsi kanssa vierailulle Lahteen – Euroopan ympäristöpääkaupunkiin vuodelta 2021 ja Kujalan käsittelykeskukseen? Voit tiedustella vierailua oheisella lomakkeella:

Täytä vierailuvarauslomake